Product Description

The VEDAQ 2000-C™ is a portable, computerized, multi-function EMI system for inspecting drill pipe and tubing. Transverse flaw detection and TRUEWALL™ solid state (Hall effect) wall monitoring functions are standard on the VEDAQ 2000-C™. It’s lightweight, compact and extremely portable design allows the VEDAQ 2000-C™ to be operated at the rig site or in a pipe yard. Commands (i.e. gain, coil, buggy adjustments) are controlled on the computer. The inspection results are displayed digitally in the software with individual channel colors for easy interpretation. The VEDAQ 2000-C™ is designed to meet most industry requirements set forth by API, DS-1, etc.

VEDAQ 2000-C™

Specifications

Technical and Performance Data

Capacity:

2 3/8" to 6 5/8" O.D. drill pipe and tubing

Functions:

Transverse flaw detection (MFL)

TRUEWALL™ magnetic wall thickness monitoring (MFD)

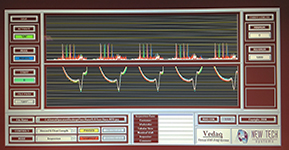

Data Acquisition:

Data acquisition system with ruggedized laptop computer (all functions performed on computer with multi-color data display)

Production Rate:

Up to 150 ft /minute

Inspection Criteria:

The VEDAQ 2000-C™ is designed to meet most industry specifications (i.e. API, DS-1, etc.)

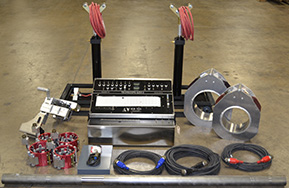

Major Components:

Electronics console

Ruggedized laptop computer with VEDAQ software

Power, signal, and buggy drive cables

High speed buggy drive with variable speed DC motors

Powerful DC magnetizing coils

Air jack set (standard or Hi-Low models available)

Buggy heads (sizes optional)

Calibration standards (sizes optional)

Method of Operation

The system is calibrated on a standard at the beginning of the job. The magnetizing coil is placed over the end of the pipe. The buggy drive and head are placed on top of the pipe and the mag coil is placed on the buggy drive. The air jacks lift the pipe so the coil & buggy will clear the pipe racks.The electronics operator then powers the buggy down the pipe and starts the computer while observing the data on the software. When the buggy reaches the other end of the pipe, the jacks lower the pipe to the racks, the buggy and coil are removed and placed on the next pipe. The process is then repeated in the opposite direction.

VEDAQ 2000-C™ Components

Buggy Drive and Calibration Standard

Graphical Digital Presentation

Optional Hi-Low Jacks